Sector Applications

Serving Industries that Demand Precision and Performance

Hima Aluminium Heat Treaters provides heat treatment, vibro finishing, and shot blasting solutions for industries where material integrity, dimensional accuracy, and fatigue resistance are critical. Our clients include major OEMs and component manufacturers across India, representing some of the most demanding industrial sectors.

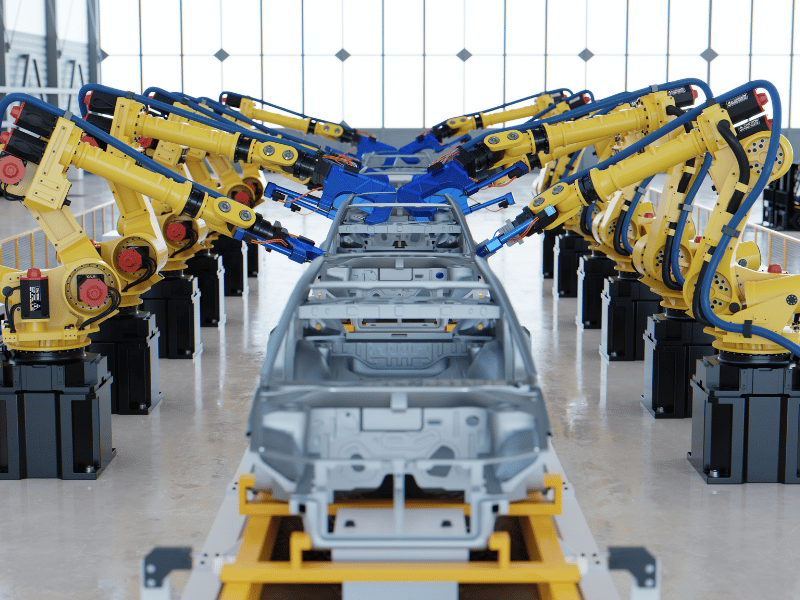

Automotive Industry

We treat a wide range of automotive parts such as engine casings, brackets, transmission housings, and structural supports. Our precision-controlled T0, T4, T5, T57, and T6 processes enhance mechanical properties and ensure long-term durability under high operational stress.

Aerospace Industry

Aerospace components require lightweight strength and flawless metallurgical consistency. We process alloys used in aircraft fittings, landing gear components, and structural parts — maintaining high reliability through controlled heat treatment and third-party certification.

Defense and Naval Equipment

We have experience serving defense and naval manufacturing sectors, processing components that meet stringent quality standards for fatigue resistance and corrosion protection.

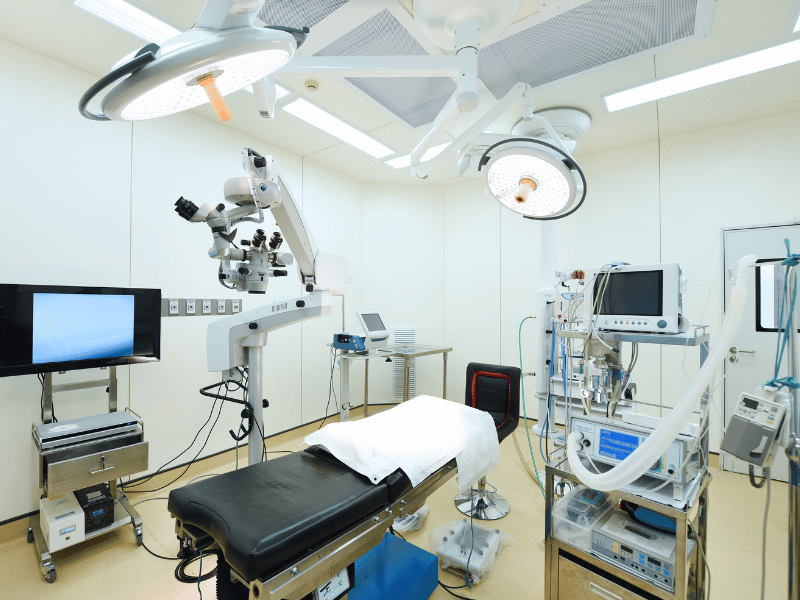

Medical and Sports Equipment

From lightweight frames to high-performance sports accessories, our aluminium treatment ensures precision finishes, enhanced surface strength, and consistent appearance.

Agricultural and General Engineering

We support agricultural equipment manufacturers and general engineering companies with dependable aluminium component treatment, ensuring each part meets international standards for hardness, microstructure, and surface uniformity.

Trusted Industrial Partners

Our growing client list includes reputed names such as:

ACE group, Bill Forge Pvt. Ltd., KDDL, IBEX Engineering Pvt. Ltd., IFB Automation, Ace Forge Ltd., Veer-O-Metals, Vinyas Mechanical Engineering Pvt. Ltd., APJ Group and Alloytech — all of whom rely on our expertise for dependable and repeatable performance.